Knowing the ins and outs of your swimming pool and how it ticks can save you plenty of money in the long run but one of the reasons why a capacitor fails, besides age, is when your pool pump runs hot which happens when you don’t pay attention to simple maintenance. What is a pool pump capacitor and what does it do?

A pool pump capacitor is similar to a battery in a car, the same reason cars need a battery to start, Pool pumps need a capacitor to start, pumps may have 1 or 2 capacitors one to start the pump, & a Run capacitor that brings the pump up to speed (3450) RPM before it switches over to AC power source.

Pool Pump Capacitors are usually the first component to go in any pool pump and they’re easy to fix. Swap them out and you’re good to go. The hard part is opening up the pump housing and getting to the actual part which are usually older pumps on older systems.

Introduction:

Pool pump capacitors are essential components of pool pump motors, playing a crucial role in ensuring efficient operation. These capacitors provide the necessary starting torque and help maintain stable voltage during the motor’s operation. Understanding the function and importance of pool pump capacitors is vital for pool owners looking to maintain their pool pump systems. By recognizing the signs of capacitor failure and knowing how to select and replace them, pool owners can avoid disruptions in their pool’s circulation and filtration processes. In this guide, we will explore the role of pool pump capacitors, how to identify issues, and the steps to take for proper replacement, ensuring the continued functionality of your pool pump motor.

Pool Pump Capacitor

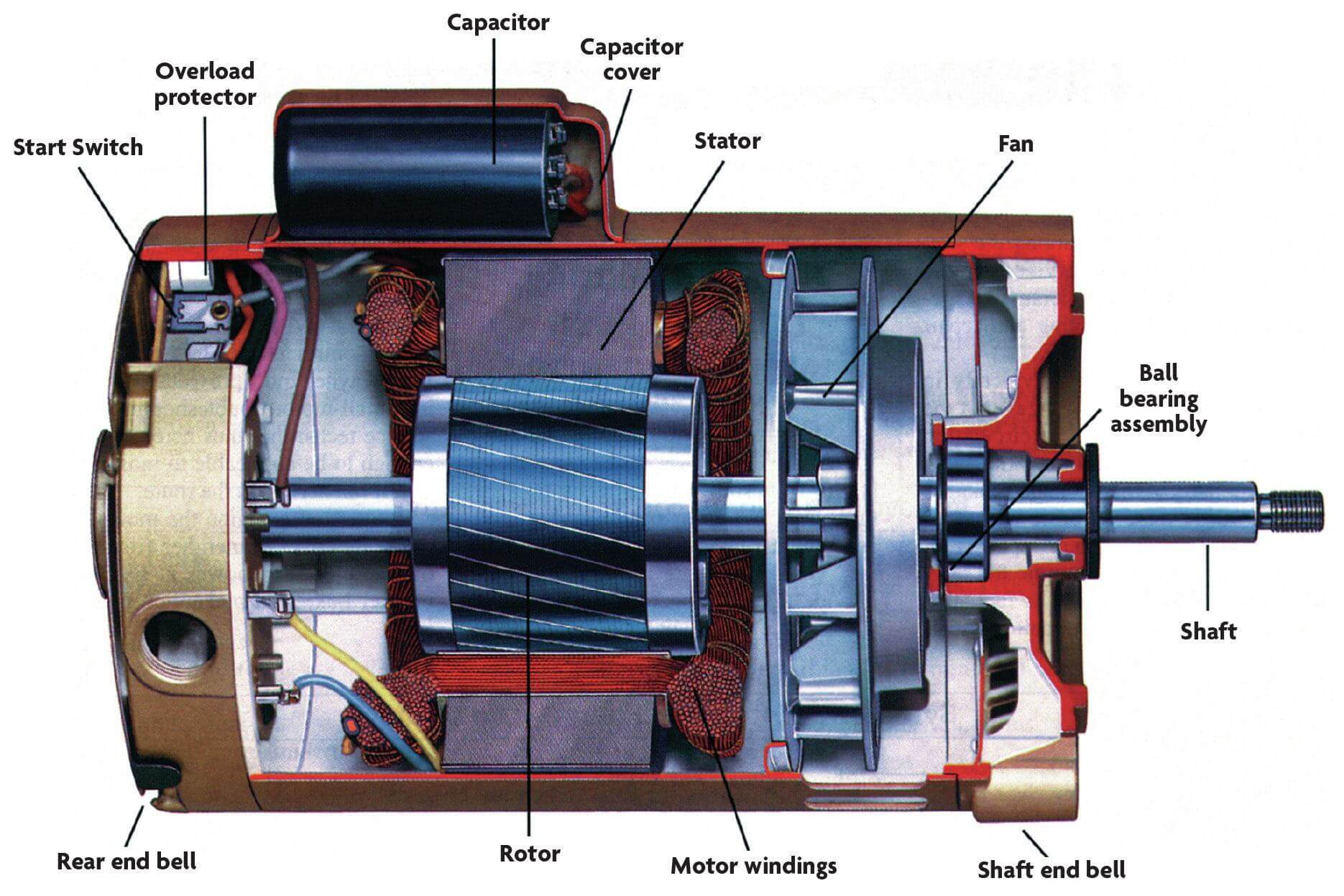

A Pool pump capacitor is a cylindrical electrical device about 3 to 4 inches long, but some models may be smaller. Some pool pump systems like the 1.5 and 2.0 hp Superpump by Hayward require two capacitors located under the motor’s housing. One capacitor helps give a little push of energy enabling the start of the pump and one helps it keep running at higher RPMs.

Either way, a pool pump capacitor is an essential electrical component of a pool’s pumping system, and without it, a pumping system will not work properly. Most pool pumps need to get up to a speed of 3450 RPM before they can run off another energy source.

Some pool pump systems require two capacitors. One capacitor starts the pump and one helps it keep running. Either way, a pool pump capacitor is an essential component of a pool’s pumping system, and without it, a pumping system will not work properly.

What Does a Pool Pump Capacitor Do

How Do I Know if My Pump Capacitor is Bad

If you come out to your pool and find the pool pump motor off when it’s supposed to be running without a problem with external power, a timer, or a breaker then you need to test the capacitor when everything else checks out. The good news is that this electrical component is fairly inexpensive and easy to replace.

- The 1st method to know if a capacitor is dead is to use your ears-When the pool pump turns on, listen for a quiet buzz or hum. This sound indicates that the pool pump capacitor has become dead

- The 2nd method is to know how old the component may Standard pool pump capacitors are only good for around 5000 starts before they go bad.

- The third method to see if a capacitor is bad is to use your nose-When your pool pump tries to turn on, the capacitor may be bad if you can smell a burnt electrical smell.

- The next method involves physically testing the Capacitors inside the housing of the pump

First, make sure the power is turned off to the pump.

- Then before you touch the wires on the capacitor, take any tool with an insulated handle and tap across two terminals on the capacitor, which will store a charge. If you touch them with bare fingers before discharging them, you might get a little zap.

- There will be an electrical spark when you do this so make sure you are only touching the capacitor with the screwdriver.

- After you release the capacitor’s charge, it’s safe to remove the capacitor from the larger cylinder.

- Use a multimeter on each of the prongs to test the capacitor. Use the lowest ohm setting, and if the meter stays at 0, it’s gone bad.

Pool Pump Capacitor Replacement

When it comes to replacing a pool pump capacitor, it’s essential to follow a systematic approach to ensure safety and proper functionality. Here’s a step-by-step guide:

- Turn Off Power: Before starting any work, make sure to turn off the power to the pool pump at the circuit breaker or disconnect switch. This step is crucial to prevent electrical shocks or accidents during the replacement process.

- Discharge Capacitor: Capacitors can retain an electrical charge even after the power is turned off, so it’s important to discharge them before handling. Use an insulated screwdriver with a rubber handle to short the terminals of the capacitor to discharge any remaining energy safely.

- Identify Capacitor: Locate the capacitor within the pool pump motor housing. It’s typically a cylindrical or oval-shaped component with wires connected to it. Take note of the capacitor’s specifications, including its voltage rating and capacitance value, as you’ll need to select a replacement with matching specifications.

- Remove Old Capacitor: Disconnect the wires from the terminals of the old capacitor, taking note of their positions for reconnection later. Depending on the mounting method, you may need to unscrew or release the capacitor from its mounting bracket.

- Install New Capacitor: Once the old capacitor is removed, install the new capacitor in its place. Ensure that the replacement capacitor has the same specifications as the original one. Secure the capacitor in its mounting bracket and reconnect the wires to the appropriate terminals, following the notes you made earlier.

- Test Operation: Before restoring power to the pool pump, double-check all connections to ensure they are secure and correct. Once everything is in place, turn the power back on and test the operation of the pool pump. Listen for any unusual noises and observe its performance to ensure the capacitor replacement was successful.

- Monitor Performance: After the replacement, monitor the performance of the pool pump over the next few days to ensure it operates smoothly and efficiently. Keep an eye out for any signs of trouble, such as unusual noises, overheating, or reduced performance, which may indicate further issues that need addressing.

By following these steps carefully, you can safely and effectively replace the capacitor in your pool pump, ensuring continued operation and enjoyment of your pool. If you’re unsure about any aspect of the replacement process, it’s always best to consult a professional technician for assistance.

Why Won’t My Pool Pump Turn On?

- The external Power outage breaker tripped

- Pool timer-ensure that it reset to cycle properly

- Clogged Pump Impeller-Clean out impeller-Look for the reset button on the back motor

- Broken pump Capacitor

- Air locked

- Overheated motor from being covered

- The pump shaft is seized

- Clogged Pump Basket .……………………………………………………………………………. Read more

How To Find the Right Capacitor For Your Pool Pump Motor

To find the right capacitor for your pool pump motor, you’ll need to consider several factors to ensure compatibility and proper operation. Here’s a guide to help you:

- Check Motor Specifications: Start by checking the specifications of your pool pump motor. Look for information such as the voltage rating, horsepower (HP), and whether it’s a single-phase or three-phase motor. These specifications will determine the type and capacity of the capacitor required.

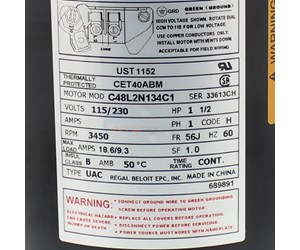

The capacitor barrel label has the component’s part number; along with its voltage and microfarad (MFD, μF) ratings. - Inspect Old Capacitor: If you’re replacing an existing capacitor, inspect the old capacitor to determine its specifications. Note down details such as voltage rating, capacitance value (in microfarads, µF), and whether it’s a start capacitor or run capacitor. This information will guide you in selecting a suitable replacement.

- Match Capacitor Specifications: Ensure that the replacement capacitor matches the specifications of the original or existing capacitor. This includes matching the voltage rating and capacitance value precisely. Using a capacitor with different specifications could result in improper motor operation or damage.

- Consider Mounting Style: Pay attention to the mounting style of the capacitor, as it should match the mounting configuration of your pool pump motor. Capacitors come in various shapes and sizes, including cylindrical, oval, and box-shaped. Choose a capacitor with a mounting style that fits securely within the motor housing.

- Consult Manufacturer or Manual: Refer to the manufacturer’s documentation or user manual for your pool pump motor. It may provide specific recommendations or requirements for the capacitor, helping you select the right one. If you’re unsure or have questions, don’t hesitate to contact the manufacturer or a qualified technician for guidance.

- Seek Professional Advice: If you’re unsure about which capacitor to choose or how to properly install it, consider seeking advice from a professional technician or electrician. They can help you identify the correct capacitor for your motor and ensure it’s installed correctly for safe and efficient operation.

*Use this Parts Page to Match the Proper Part

By following these steps and considerations, you can find the right capacitor for your pool pump motor, ensuring compatibility and optimal performance. Proper selection and installation of the capacitor are essential for maintaining the efficiency and longevity of your pool pump system.

Conclusion:

Capacitors are usually the first to go in any pool pump and they’re a quick fix. Simply pop them out and replace them and you should be good to go. The hard part is opening up the pump and getting to the actual part. Mr. Pool Man has the most commonly used capacitors for pool pumps available online at excellent prices!

No more searching through hundreds of rating combinations, just pick the right microfarad rating and it should be a straight swap with your existing capacitor. Now if it’s a motor problem, then Mr Pool Man recommends that you get a new pool pump altogether because once your pump motor has failed, it won’t be long till other components of your pump start failing as well.

References:

– How To Find the Right Capacitor For Your Pool Pump Motor

– How To Find the Right Capacitor For Your Pool Pump Motor

FAQ’s

- What is a pool pump capacitor? A pool pump capacitor is a component of the pool pump motor, particularly in single-phase induction motors. It stores electrical energy and helps provide the necessary starting torque to the motor, ensuring smooth operation.

- How do I know if my pool pump capacitor is bad? Signs of a faulty pool pump capacitor include difficulty starting the pump, humming noises from the motor without starting, intermittent operation, overheating, visible damage to the capacitor, reduced pump performance, and electrical issues such as tripped breakers or blown fuses.

- Can I replace the pool pump capacitor myself? Yes, you can replace the pool pump capacitor yourself if you have the necessary knowledge and skills. However, it’s essential to follow safety precautions and ensure you select a replacement capacitor with matching specifications to avoid damaging the motor.

- How do I find the right capacitor for my pool pump motor? To find the right capacitor, check the specifications of your motor, inspect the old capacitor (if replacing), match capacitor specifications including voltage rating and capacitance value, consider mounting style, consult the manufacturer or manual, and seek professional advice if needed.

- What are the types of pool pump capacitors? There are two main types of pool pump capacitors: start capacitors and run capacitors. Start capacitors provide the initial boost of power to start the motor, while run capacitors help maintain a consistent voltage during operation.

- How often should pool pump capacitors be replaced? Pool pump capacitors typically last several years but may need to be replaced if they show signs of failure or wear. It’s recommended to inspect the capacitor regularly and replace it if any issues are detected.