If properly designed, desalination plants that use RO can consistently deliver high-quality water to consumers. Even more importantly, the quantity of water stored in the ocean is so vast it’s virtually inexhaustible, so desalination is a completely drought-proof source of water. So why don’t cities take advantage of Desalination for the use of drinking water? Why is desalination so expensive?

- Energy-intensive process

- High capital costs for infrastructure

- Complex maintenance requirements

- Expensive materials for filtration

- Environmental impact mitigation costs

- Regulatory compliance expenses

- Research and development costs

- Geographic location impacts the cost of intake and discharge structures

Besides clean-up costs from the operation, a family of 5 consumes an average of 325,851 gals. per/year. That is just to produce 10-13 kilowatt-hrs(kWh) per 1,000 seawater gallons that need to be processed.

Introduction:

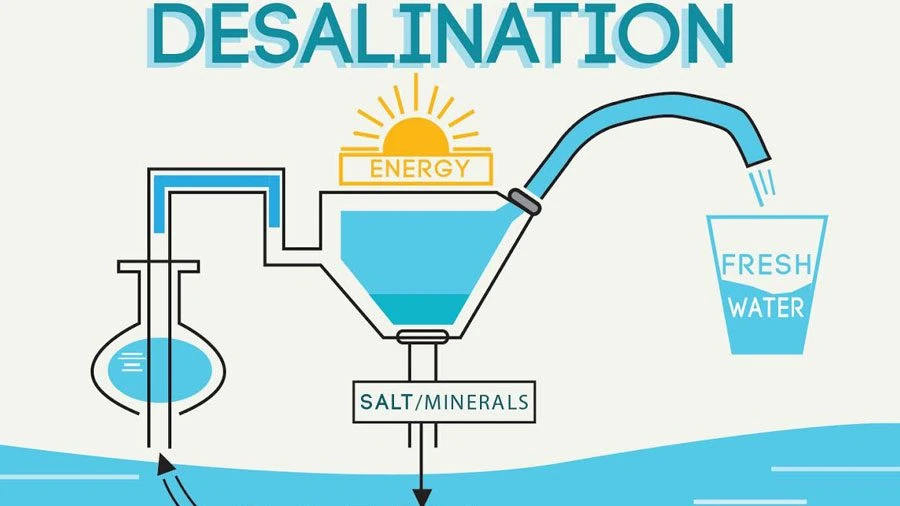

Desalination, a process that removes dissolved salts and minerals from seawater or other contaminated water, has become a technological solution to the global water shortage. While this process is a viable means to supplement our water supply, it is commonly understood to be an expensive venture. This article seeks to shed some light on the factors contributing to the high cost of desalination, explaining the intricacies behind the complex technologies, energy requirements, environmental impacts, and infrastructure needed. The aim is to provide a clearer understanding of why desalination is generally considered costly.

Understanding the Expense Inherent in Water Desalination Plants

Water, one of our most crucial resources, is becoming scarcer in many parts of the world due to climate change and increased population and consumption. Desalination, the process of removing salt and other impurities from seawater, provides a potential solution to this issue. However, it’s important to understand why operating a desalination plant is often a costly endeavor.

One of the main reasons a desalination plant is expensive is because it requires a great deal of energy. Powering a desalination plant can be energy-intensive. The process of converting seawater into usable drinking water involves various stages of filtration, and each stage requires energy. This aspect of running a desalination plant contributes significantly to the overall operational costs.

The science and engineering behind the desalination process are complex. It involves sophisticated technology and specialized infrastructure. The materials used in constructing a desalination plant are costly as they need to be corrosion-resistant and durable enough to withstand the harsh maritime environment. Constructing a desalination plant, therefore, requires substantial financial investment.

Another cost factor in running desalination plants is the maintenance and replacement of components. Regular inspection and maintenance are crucial to keep the plant operating efficiently. Over time, parts of the plant may become worn and need replacing, adding to the ongoing costs.

Then there are environmental considerations related to desalination plants that contribute to the expense. The disposal of the brine residue, a byproduct of the desalination process, presents both a logistical and environmental challenge. Moreover, desalination plants are often located near coastal areas where they can have adverse impacts on marine ecosystems.

These factors – the high energy consumption, the initial investment in plant construction, the ongoing maintenance, the challenges in waste disposal, and the potential environmental impact all contribute to making desalination an expensive solution. It’s a delicate balancing act between solving water scarcity problems and managing the costs and effects associated with these plants.

However, with advancements in science and engineering, there is the potential for making desalination plants more cost-effective and environmentally friendly. Continued research and development could lead to more innovative methods of desalination that could reduce its cost and impact, making it a more viable option for boosting water resources in the future.

To conclude, understanding the inherent expense of water desalination plants is vital as we seek to expand our water resources. Despite the costs, desalination continues to play an essential role in providing water in many parts of the world where fresh water is scarce. With further and future advancements in plant science and engineering, the cost dynamics of desalination plants can be improved, ensuring a sustainable water supply for our growing population.

What are the 3 Methods of Water Desalination Plant

Three methods and principle methods of desalination exist thermal, electrical, and pressure. The oldest and 1st method is thermal distillation, which has been around for thousands of years. In thermal distillation, the water is boiled, and then the steam is collected, leaving the salt behind.

- The vaporization phase change requires significant amounts of energy. More modern methods of distillation make use of various techniques, such as low-pressure vessels, to reduce the boiling temperature of the water and thus reduce the amount of energy required to desalinate.

- A second major type of desalination utilizes electric current to separate the water and salt. Typically, an electric current will be used to drive ions across a selectively permeable membrane, carrying the dissociated salt ions with it. A key characteristic of this method is that the energy requirement depends on how much salt is initially present in the water. Consequently, it is suitable for water with initial salt concentrations but too energy-intensive for seawater.

- A third principle method of desalination is reverse osmosis, in which pressure is used to drive water through a selectively permeable membrane, leaving the salt behind. Similar to electrically-driven separation, the amount of energy required for desalination depends on the initial salt content of the water. Again, this renders reverse osmosis unsuitable for seawater purification.

The Role of Ocean Desalination in Supplying Water

Ocean desalination has emerged as a major player in addressing the world’s growing demand for water. With over two-thirds of the Earth’s surface covered by the ocean, desalination provides a way to convert this vast but previously unusable water resource into a viable means of meeting human needs. However, ocean desalination is not a simple solution, and it comes with its own set of challenges.

Desalination involves removing the salt and other minerals from seawater to make it suitable for human consumption or industrial use. This process, while promising, requires a significant amount of energy and specialized equipment. The need to desalinate on a massive scale to meet the demands of large populations further increases the costs associated with this process.

Not only is the technology required to desalinate water expensive, but the process also has environmental implications. It generates a saline brine waste product that must be properly managed to prevent adverse effects on marine life. Adding to this, running desalination plants requires substantial energy, often sourced from fossil fuels, which contributes to climate change.

Despite this, the role of ocean desalination in supplying water cannot be downplayed. Many regions of the world already rely heavily on desalinated water. For instance, in places where freshwater resources are scarce or polluted, desalinated water serves as a vital lifeline. Furthermore, as the effects of climate change continue to intensify, the importance of ocean desalination in securing stable and reliable water resources for the future will only increase.

As water scarcity continues to be a pressing issue worldwide, we may have no choice but to turn to the sea. However, as we venture further into the ocean for our water needs, we must also be mindful of the cost – both monetary and environmental – of desalination. The true expense of ocean desalination is not just in the infrastructure or the energy required to desalinate, but it is also in the environmental impact of the process.

While we cannot eliminate the need for ocean desalination, we can work towards making it more affordable and environmentally friendly. Research is ongoing to develop more efficient desalination technologies and renewable energy sources to power these plants. Moreover, there is also a need to invest in more sustainable ways of managing the byproducts of the desalination process.

Some takeaways: ocean desalination plays a significant role in supplying water across the globe. Understanding its cost is not just about knowing how much it takes to get that glass of water from the sea to the tap, but also about comprehending the environmental implications. Despite the costs, it is a necessity we cannot ignore, and with further research and investments, we can make desalination a more sustainable option for securing our future water resources.

Carlsbad Desalination Water Plant: A Case Study

The Carlsbad Desalination Water Plant, located in San Diego, California, serves as a prime example when discussing the cost associated with desalination plants. In the heart of California, the Carlsbad plant has been on the front line in the quest for fresh water.

A significant concern underlying the high cost of desalination is the complex procedure involved in making ocean water potable. The Carlsbad plant, one of California’s greatest investments in the field of water production, addresses this issue. It utilizes advanced technology to transform water from the neighboring bay into fresh water, suitable for human consumption.

A significant concern underlying the high cost of desalination is the complex procedure involved in making ocean water potable. The Carlsbad plant, one of California’s greatest investments in the field of water production, addresses this issue. It utilizes advanced technology to transform water from the neighboring bay into fresh water, suitable for human consumption.

Funded by the county water authority, the Carlsbad plant came into existence to reduce dependency on distant water sources. San Diego is at the far end of the extensive California water system. Consistent water supply has been a persistent issue in the region, pushing the need for local, reliable sources like the county water authority-operated desalination plant.

Engaging in the transformation of heavy saline water from the bay into fresh water isn’t as simple as it appears. The Carlsbad plant, similar to any desalination plant, must filter salt and other impurities meticulously to ensure every drop is safe to consume. This process requires a considerable amount of energy and specialized equipment, contributing to the high operational costs.

Moreover, while discussing the Carlsbad plant, one cannot overlook the ecological impact. Like other plants in California, the Carlsbad plant must carefully manage the saline byproduct or brine. Returning concentrated salt water to the bay requires strategic planning to avoid damaging sensitive marine ecosystems, which, again, adds to the total expenditure.

Despite these challenges, the Carlsbad plant in San Diego, California, continues to serve as a critical water source. It fulfills approximately 10% of the county water supply demand, providing fresh water to many households across the region.

It’s the energy costs associated with desalination that make the technique once the stuff of engineers’ pipe dreams such a pricey endeavor. The San Diego County Water Authority has agreed to purchase the water from Poseidon Water, the Carlsbad plant’s operator, for about $2,000 an acre-foot for 30 years after the plant goes online. (An acre-foot is the volume of water that would cover an acre with one foot of water — about 326,000 gallons, or 1,234 cubic meters.) The trouble is, that cost is almost double what the agency now pays for water, and will raise ratepayers’ bills by about 10 percent, according to NBC News.

Nevertheless, the discussion surrounding the cost efficiency of desalination plants is ongoing. Supporters argue that in an era where freshwater scarcity is rampant, investments like the Carlsbad plant provide a lifeline. Critics, on the other hand, emphasize the need for more affordable and environmentally friendly solutions.

Understanding the workings and costs of a plant like the Carlsbad desalination water plant can provide significant insights. It delineates the challenges and expenses involved while also stressing the importance of technological advancements to achieve affordable desalination. Throughout California, and in San Diego in particular, the conversation around the cost and value of plants like the Carlsbad plant is far from over.

Operational and Environmental Costs of a Desalination Plant

The operational and environmental costs of a desalination plant are pivotal factors in understanding why desalination can be an expensive venture. At the core of a desalination plant’s operation are the engineering resources it requires, and these costs are frequently cited as reasons for the significant expense of establishing these plants. However, it’s important to also recognize the National Sanitation Foundation’s (NSF) role in setting standards for these plants which can also contribute to the costs.

Regardless of their specific makeup, a desalination plant requires robust and efficient energy sources to desalinate water. Such energy-intensive processes contribute to the bulk of the operational costs. Moreover, excessive energy use triggers a domino effect on the climate due to increased carbon emissions.

This outlines the unique dichotomy presented by desalination plants – while they supplement essential water needs, their operation has the potential to exacerbate climate change. These complexities make the state’s involvement in water management strategies a necessity in striking a balance.

Most environmental advocates view desalinization (or desalination)‚ as a last resort for providing fresh water to needy populations. It’s not the final solution but only another route to take us where we need to go. Right now, it can answer a lot of questions even though there is a price to pay to do it.

Coral reefs require marine organisms to flourish. But as desalination takes place, numerous organisms, plankton, and fish larvae are vacuumed up in the saltwater that goes to the plant. The tiniest of organisms that are required to feed and are home to start the basis of the ocean food chain are affected by intake pumps used by Desalinization plants to pull salt water to produce fresh drinking water.

This is the beginning that plays a role in the death of coral reefs, and it decreases the bottom of the marine food chain. When there’s a disruption to the food chain, the entire biodiversity of the ocean is at risk, from the smallest creatures to the biggest creatures.

According to the U.S. Department of the Interior: the sheer cost of operating a desalination plant is what has kept them from being more widely used. For most governments or private companies, the cost is too high even to consider. Most desalination plants are in the Middle East, where the demand is high, and oil-rich countries have the money to fund the plants.

Despite the higher costs, desalination has been lauded for its potential to solve water scarcity issues, hence the steady rise in the number of desalination plants around the world. As technology evolves, it’s important to note that advancements in engineering could potentially lower costs. We’ve seen evidence of this in the Carlsbad Desalination Water Plant, where innovative engineering significantly reduced energy usage, subsequently driving down operational costs. This is one of the factors that make desalination costs a dynamic subject.

Another perspective to look at is the potential social costs of operating desalination plants. While the primary goal of these plants is to provide a sustainable water source, the process results in brine disposal, which needs careful management to minimize environmental harm. Also, not addressing these issues could escalate into more costly situations down the line, requiring unexpected additional resources.

Furthermore, it’s also critical to consider the costs following the desalination process. As the water is desalinated, additional post-treatment processes may be required before the water is fit for human consumption, resulting in more costs. Therefore, while desalination is expensive, the adoption of this water treatment method is often a result of weighing benefits against costs in a wider context.

Some Takeaways: The desalination plant’s operational costs encompass the expenses related to engineering, energy, and environmental protection. At a glance, the expense of desalination is justified considering the invaluable contribution it makes towards addressing global water scarcity. However, it’s also crucial to remember that a desalination plant’s expense is a dynamic subject that requires continuous attention and study to achieve cost-efficiency and environmental sustainability.

How Are Water Desalination Plants Powered

Water desalination, the process of removing salt and minerals from seawater to produce fresh water for drinking or irrigation, has become an essential part of many regions’ water resources. However, desalination plants, due to their large-scale operations, pose an interesting question to civil and mechanical engineering professionals alike: how are these plants powered?

Usually, energy is the driving force behind water desalination, and it’s essentially the heart of the plant’s machinery. The energy used in desalination plants often comes from either fossil fuels or electricity. Regardless of the source, the energy required for these plants is substantial, and this links directly to the cost of producing fresh water via desalination.

Providing a plentiful supply of water for human consumption and agricultural use is no small task. The water which flows from our taps at home and irrigates our crops, in many regions, has been desalinated. Engineering bodies worldwide are tasked with ensuring this supply, employing cutting-edge plant designs and operations, all the while, utilizing various energy sources to power the plant and process huge amounts of water.

In addition to this, desalination plants also have another important energy consideration: the energy recovery system. These systems recapture and recycle some of the energy used during the desalination process, thus improving the plant’s energy efficiency and ultimately reducing the cost associated with operating the plant. The advent and improvement of these systems are a challenging field of engineering as the industry seeks to drive down the operational costs of these plants.

A primary example of this is the Carlsbad Desalination Water Plant, a trailblazer of modern desalination plants. In addition to using traditional energy sources, this plant put energy recovery systems to greater use to offset the cost of operation and create a green energy print despite the inherent expenses associated with water desalination on such a scale. It is a living case study of how to power and run a water desalination plant effectively and efficiently.

Yet, the expense inherent in desalination plants cannot be fully eliminated due to the sheer volume of energy required for the process. Thus, the understanding and control of how water desalination plants are powered remain an essential part of the operation, determining both the environmental and economic impact.

In conclusion, energy sourcing, use, and recovery are all vital components in the power operations of desalination plants, affecting the production of fresh water and the role of ocean desalination in supplying water around the world. Therefore, it is beneficial for the engineering community, environmental bodies, and policymakers to continually seek optimized and sustainable energy utilization strategies within desalination, thereby making strides in creating a more sustainable world.

Highlighting the Disadvantages of Ocean Desalination

Ocean desalination plays a crucial role in supplementing our water supply, particularly in regions where fresh water is scarce. However, despite the seeming abundance of seawater, desalination is an expensive process, prompting many to question its economic viability.

One of the most significant expenses in ocean desalination is the desalination plant itself. These facilities are intricate and vast, requiring substantial investment for construction. Furthermore, membranes, a core component in the desalination process, are expensive to manufacture and maintain. The upkeep of these membranes, which are used to filter out the salt and other impurities from the seawater, also contributes to the overall operational cost.

Another factor that adds to the expense of desalination is the energy needed. Desalinating water is an energy-intensive process. Seawater desalination plants use a significant amount of energy in the desalination process compared to the conventional treatment of surface water or groundwater. The expense of energy alone can make the rate of desalinated water much higher than other water sources.

Aside from costs related to the plant and energy, the environmental impact of ocean desalination should not be overlooked. The byproduct of desalination, a concentrated brine that contains salt and other substances, must be safely disposed of, which in itself is a costly and complex process. Furthermore, ocean-based intake and discharge systems can harm marine environments, which can result in mitigation expenses or legal repercussions.

The Carlsbad Desalination Water Plant serves as a good case study for understanding these costs. As one of the largest desalination facilities, it provides valuable insights into the expenses associated with this process. Despite its capacity to produce an impressive amount of desalinated water, it’s also a testament to the financial burden of this water source.

As with any process, desalination has by-products that must be taken care of. The process of Desalinization requires the use of cleaning chemicals and pre-treatment chemicals that are added to the water before desalination to make the treatment more efficient and successful.

The Chemicals used in the process are substances that include chlorine, hydrochloric acid, and hydrogen peroxide; they can’t be used continuously and have to be replenished. Once they’ve lost their ability to clean the water, these chemicals are dumped, which becomes a major environmental concern. These chemicals often find their way back into the ocean, where they can poison plant and animal life. Brine is the side product of the Desalinization process.

While the purified water goes on to be processed and put into human use, the wastewater that is left over, which has a supersaturation of salt, must be disposed of. Most desalination plants pump this brine back into the ocean, which presents another environmental drawback. Ocean species are not equipped to adjust to the immediate change in salinity caused by the release of brine into the area.

Some Takeaways– Ocean desalination, while providing an additional source of water, comes with a high price tag. There’s an array of factors, from the cost of constructing and operating desalination plants, the expense of energy for the desalination process, and the environmental costs of handling waste products, that make this technology expensive. However as the water demand continues to exceed supply in many regions, more research and innovation are needed to make desalination a more cost-effective and environmentally sustainable solution in our toolbox for addressing water scarcity.

Stanford’s Research on Improving Desalination Plant Efficiency

The topic of water desalination has been the focus of much research, given its importance to the world in these times of fluctuating freshwater supply. Stanford’s research into the efficiency of desalination plants has significantly contributed to this field.

Their research seeks to review and improve the state of desalination technology which, as we’ve seen in the review of the Carlsbad Desalination Water Plant, holds profound implications for our state’s, and indeed the world’s, water supply. Their research explores the operational and environmental costs of a desalination plant, giving us insight into what makes the process expensive.

Their research has been a link to understanding why desalination is so critical, and why it’s a technology that the world can’t afford to overlook. Stanford’s research reaffirms the questions that often arise in the review of these desalination processes. What is the state of desalination technology today? Can it be made more efficient, and thus more affordable? These are some of the questions answered through their research for the future.

In their recent research publications, they have studied various ways to improve the efficiency of desalination plants. One of the key takeaways from their research has been the potential for renewable energy sources to power the plant, which we saw in the examination of “How Are Water Desalination Plants Powered?”. This use of renewable energy could not only lessen the environmental impact but also potentially reduce the day-to-day operational costs. It’s a game-changer in the world of water desalination, creating a viable link between sustainability and accessing water resources.

By reframing our approach, this powerful research could address the disadvantages of ocean desalination. It doesn’t mean that the questions surrounding desalination are completely answered, but with each passing day, this research brings us closer to a more sustainable and efficient process. Thus, Stanford’s research provides a comprehensive review of the state of desalination technology in the world today, plotting a course for a future where clean water is accessible to all.

Advancing the water desalination technology is paramount. Current state techniques involve energy-intensive processes which are expensive both in terms of operational and environmental costs. Therefore, although humanity has been able to solve the question of producing freshwater through desalination, its adoption as a daily water supply in many parts of the world is still an issue being researched – another reason why Stanford’s research is so valuable to the state of our day-to-day global water supply structure.

In conclusion, Stanford’s research in this crucial field gives us a link to the solutions that can address the crucial question of making water desalination more efficient and affordable. As we persist in our efforts and continue to build on their research, the day might come when freshwater scarcity is no longer a pressing issue, altering the state of water supply in the world forever.

Conclusion:

The expense of desalination is attributed mainly to the energy-intensive processes involved, the costs for maintenance, and the environmental impacts that it may generate. The continuous advancements in technology are anticipated to provide more economical and environmentally friendly solutions in the future. It’s noted that a significant understanding and consideration of the costs related to the desalination process are essential for societies that lack freshwater resources.

If properly designed, desalination plants that use Reverse Osmosis (RO) can consistently deliver high-quality water to consumers. Even more importantly, the quantity of water stored in the ocean is so vast it’s virtually inexhaustible, so desalination is a completely drought-proof source of water. So why don’t cities take advantage of Desalination for the use of drinking water? Because of the new technology, the process is still on the expensive side. Here are some costs.

Besides clean-up costs from the operation

Ocean Desalination costs $2,000 & $2,500 an acre-ft.

Brackish Desalination ranges-$1,000-$2,000 an acre-ft.

1 acre-ft. is equal to 325,851 gals.-the amount of H2O a family of 5 uses per/year, consuming an ave. of 10-13 kilowatt-hrs(kwh) per 1,000 gals/processed

For more great articles on Environmental issues like this one on Wetlands stay here on MyWaterEarth&Sky- Wetlands can support waterbirds, fish, amphibians, reptiles, and plant species during important life stages they are used to gather statistics and information but are hard for an ordinary layman like …………………………………………………..… Continue reading

References:

EPA-The Disadvantages of Desalination

Caniry-What Happens To The Salt From Desalination Plants?

FAQ’s

1. What is desalination, and why is it considered expensive?

Desalination is a process that removes dissolved salts and minerals from seawater or other contaminated water. This process is a viable solution to the global water shortage. However, desalination is considered expensive due to several factors. First, it requires a substantial amount of energy, contributing to high operational costs. Second, constructing a desalination plant requires significant financial investment due to the specialized infrastructure and the cost of materials. Lastly, there are maintenance costs and environmental concerns related to the disposal of the brine residue after desalination.

2. What impact does desalination have on the environment?

Desalination has a few environmental impacts. First, it generates a byproduct known as brine, which is a concentrated solution of salt and other substances. The disposal of this brine presents logistic and environmental challenges. Second, the location of desalination plants near coastal areas can adversely affect marine ecosystems.

3. What are some potential ways to make desalination more cost-effective and environmentally friendly?

With advancements in science and engineering, there is the potential for making desalination plants more cost-effective by adopting more efficient and innovative methods of desalination. Renewable energy sources, for example, could lessen the environmental impact and reduce operational costs. Furthermore, research into alternative, sustainable ways of managing desalination byproducts could also lead to a more eco-friendly process.

4. What role do desalination plants play in our water supply?

In many parts of the world where fresh water is scarce, desalination plants play an essential role in providing water. It provides a potential solution to water scarcity, converting an abundant resource, seawater, into a usable form. Despite the costs, desalination continues to contribute to our water resources, and with further advancements in plant science and engineering, its cost dynamics and impacts can be improved.